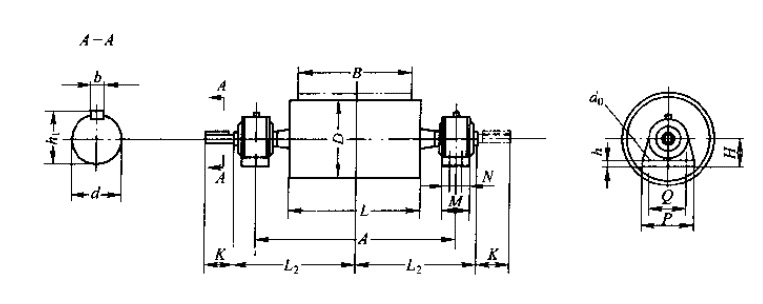

Drive pulley for conveyor system

The diameter and length of the driving drum comply with the provisions of "GB/T988-1991 Basic Parameters and dimensions of belt conveyor idlers".

This series of transmission drums can be divided into light, medium and heavy duty according to the carrying capacity. among

Lightweight: single attached plate welded cylinder structure with single key connection between shaft and hub.

Medium: single attached plate welded cylinder structure with expansion sleeve connecting shaft and wheel hub.

Heavy duty: shaft and wheel hub for expansion sleeve connection, cylinder for cast welding structure, there are one-way shaft and two-way shaft two.

Some rollers of the same diameter are also equipped with several journal and bearing seat center distances.

The surface of the driving drum is all rubber surface, and its shape has three kinds: left herringbone, right herringbone and diamond. When the user needs smooth driving roller, special order is required.

The cylinder bearing seat is lubricated by pressure injection nozzle. If centralized lubrication is required on order, we will provide additional nozzles for customers.

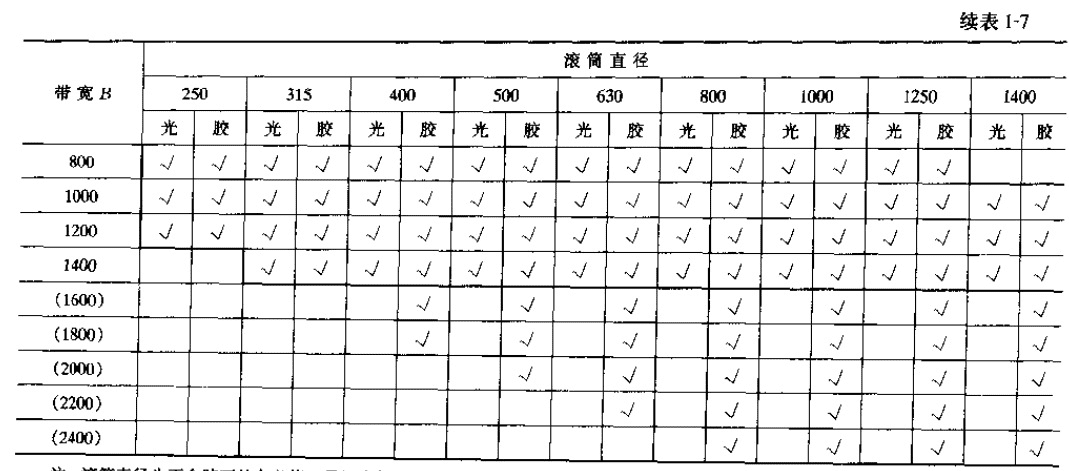

Tail pulley/Bend pulley

The diameter and length of the reversing drum comply with the provisions of "GB/T988-1991 Basic Parameters and Dimensions of belt conveyor idlers", as shown in the following table.

The reversing drum is divided into light, medium and heavy three kinds according to the carrying capacity. The drum structure is the same as the driving drum with the same bandwidth and diameter.

The surface of the reversing drum has two kinds of smooth surface and rubber surface. The bearing housing is lubricated in the same way as the drive drum.

Drive pulley for conveyor system

Tail pulley/Bend pulley

Operating procedure

1. A dust mask and gloves must be worn.

2. Cleaning rollers must be operated by special personnel. Before driving, check whether the equipment is running normally, whether there are defects, and whether the fasteners are loose.

3. Each batch of casting and core iron shall not exceed 75% to 80% of the volume of the drum. The maximum weight must not exceed the regulations.

4. Before loading, the roller should be fixed with a pin to avoid rotation and injury during loading.

5. After the drum is loaded with castings, the drum cover should be closed and bolted tightly. When cleaning, first start the ventilation and dust removal equipment, and then open the drum.

6. The drum cover can only be opened after the drum cover is turned to the front and fixed with a latch.

Seven. When the roller is working, personnel are strictly prohibited from approaching. There should be no castings or other things around.

8. The cover should not be opened until the impeller of the shot blasting cylinder has completely stopped rotating.

Maintenance

In order to extend the service life of the roller, it is necessary to do a good job of maintenance of the roller.

1. Regularly clean the dust and other foreign matter on the roller.

2. It is necessary to regularly check whether the welding between the drum shell and the end cover is firm.

3. Good lubrication, reduce the loss of wear.

4. Avoid overload operation and extend the service life of the drum.

Application/field of application

Roller is an important part and component of belt conveying system. The drum can effectively improve the operation of the conveying system,

Protect the metal drum from wear, prevent the slip of the conveyor belt, make the drum run in sync with the belt, so as to ensure that the belt is efficient and large

The rubber of the drum can also effectively prevent the sliding friction between the drum and the belt, and reduce the material sticking on the surface of the drum

Knot, thereby reducing belt deviation and wear

Widely used in: steel, metallurgy, coal, cement, power generation, fertilizer, grain depot, port and other industries.

Copyright @ Huizhongxing All Rights Reserved 2024

Good

Admin on March 21, 2024The product is very good and has a beautiful appearance. We will cooperate more in the future.

Good

Admin on March 16, 2024The product quality is very good.

Good

Admin on March 09, 2024Fast construction period and excellent quality.

Good

Admin on March 09, 2024The after-sales service is excellent, and we can actively communicate and solve any problems!

Good

Admin on March 09, 2024I will repurchase in the future if needed!