The slag discharge drum is a reversing drum of a belt conveyor, usually made of all steel drum.

The utility model relates to a component of a belt conveyor, in particular to a slag discharge roller.

Background technique

Belt conveyor, also known as belt conveyor, is a friction-driven machine that transports materials in a continuous manner. It is mainly composed of frame, conveyor belt, roller, roller, tensioning device, transmission device, etc. One of the important components of the drum, the conveyor belt is dragged by the friction between the drum and the conveyor belt. When the belt conveyor transport block material, block material is easy to fall on the return belt with the belt into the tail drum surface, block material between the belt and the drum, resulting in belt damage.

Utility model content

The utility model aims to provide a slag discharge roller to solve the problem that the clogging of the bottom hopper affects the screening efficiency existing in the prior art.

The utility model is mainly composed of a left and right bearing seat, an shaft and a cylinder, an shaft is fixed in the middle of the two bearing seats, a key is arranged on the shaft, the cylinder is fixed on the shaft, and a plate is arranged between the cylinder and the shaft. The technical solution adopted to solve the technical problem is that the cylinder is composed of a number of cladding plates and a rolling plate on the left and right sides, and a number of slots are arranged on the rolling surface. A number of cladding plates are uniformly arranged on the left and right sides of the rolling skin, and a gap is formed between the cladding plates.

A stop ring is arranged on the bearing seat.

A reducing plate is arranged inside the cylinder.

The working principle of the utility model is that when the belt conveyor is transporting the block material, the block material falls on the return belt and enters the surface of the tail drum with the belt, and the block material enters the inside of the cylinder through the slot on the rolling surface, and then rolls out from the gap between the covering plates on both sides of the cylinder with the rotation of the drum. This prevents block material from getting between the belt and the roller and causing damage to the belt.

The utility model has the advantages of simple structure, stable and reliable structure and long service life by arranging a gap on the surface of the same body and on both sides to facilitate the block material to enter and roll out, effectively solving the problem that the block material is damaged between the belt and the roller.

Illustrated description

The utility model is further explained in combination with the attached drawings and embodiments.

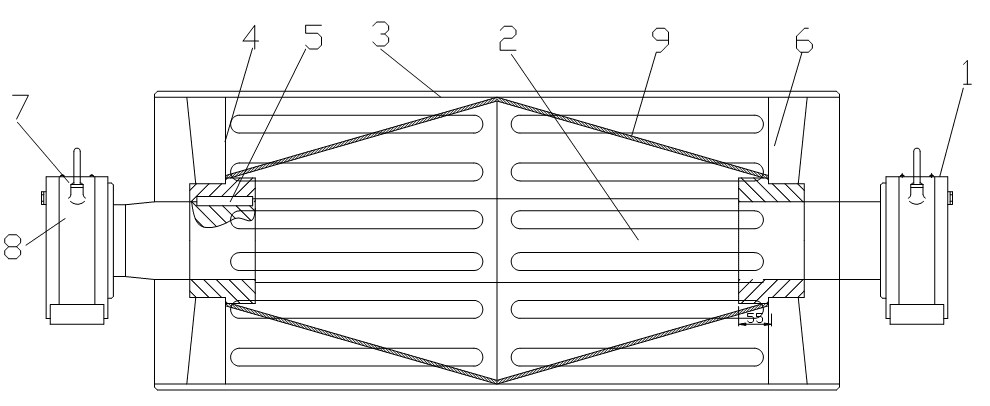

Figure 1 is a structural diagram of the utility model;

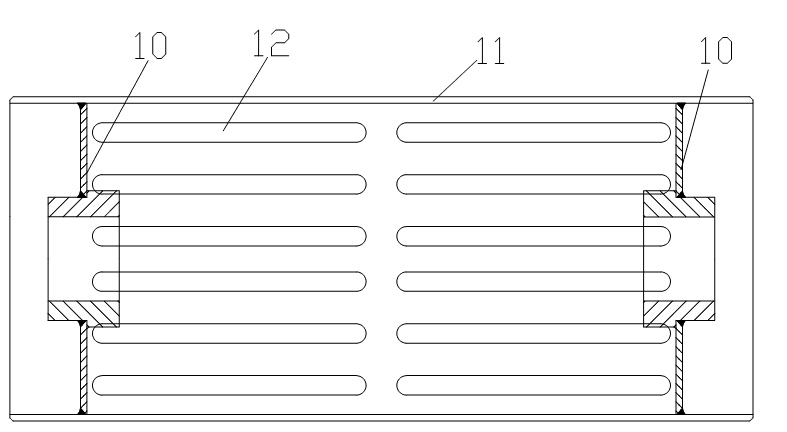

Figure 2 is a structural diagram of the cylinder of the utility model;

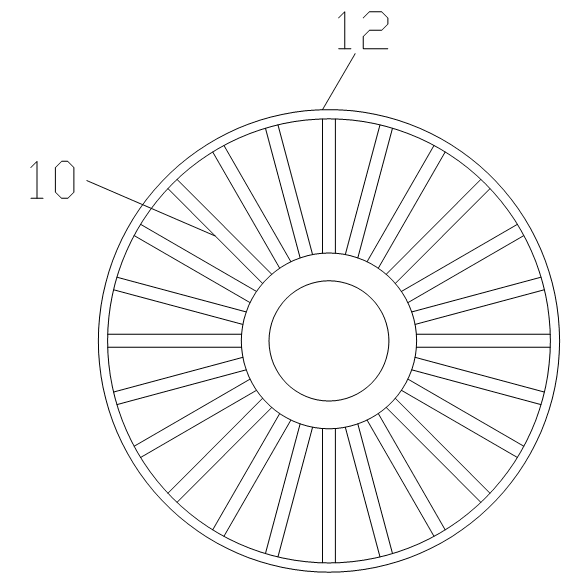

Figure 3 is a side view diagram of the cylinder of the utility model.

In the picture, 1 bearing seat, 2 shafts, 3 cylinders, 4 receiving plate ribs, 5 keys, 6 receiving plate ribs, 7 bearing seat, 8 stop rings, 9 reducing plate, 10 covering plate, 11 rolling skin, 12 slot holes.

Concrete implementation mode

As shown in Figures 1, 2, and 3: The slag discharge roller is mainly composed of bearing seat 1, bearing seat 7, shaft 2 and barrel 3, bearing seat 1 and bearing seat 7 are respectively provided with a stop ring 8, shaft 2 is fixed in the middle of bearing seat 1 and bearing seat 7, shaft 2 is provided with a key 5, cylinder 3 is fixed on shaft 2, a plate 4 and plate 6 are arranged between cylinder 3 and shaft 2, and a reducing plate 9 is arranged inside cylinder 3. The cylinder body 3 is composed of a plurality of covering plates 10 and a plurality of rolling plates 11 on the left and right sides. The surface of the rolling plate 11 is provided with a plurality of slots 12, and a plurality of covering plates 10 are uniformly arranged on both sides of the rolling plate 11, and a gap is formed between the covering plates 10.

The working principle of the utility model is that when the belt conveyor is transporting the block material, the block material falls on the return belt and enters the surface of the tail drum with the belt, and the block material enters the inside of the cylinder through the slot on the rolling surface, and then rolls out from the gap between the covering plates on both sides of the cylinder with the rotation of the drum. This prevents block material from getting between the belt and the roller and causing damage to the belt.

Copyright @ Huizhongxing All Rights Reserved 2024

Good

Admin on March 21, 2024The product is very good and has a beautiful appearance. We will cooperate more in the future.

Good

Admin on March 16, 2024The product quality is very good.

Good

Admin on March 09, 2024Fast construction period and excellent quality.

Good

Admin on March 09, 2024The after-sales service is excellent, and we can actively communicate and solve any problems!

Good

Admin on March 09, 2024I will repurchase in the future if needed!