Belt conveyor, also known as belt conveyor, is widely used in household appliances, electronics, electrical appliances, machinery, tobacco, injection molding, post and telecommunications, printing, food and other industries, objects assembly, testing, debugging, packaging and transportation. Line conveying can be selected according to the process requirements: ordinary continuous operation, beat operation, variable speed operation and other control modes; Line body selection according to local conditions: straight line, curve, slope and other line body form conveying equipment including: belt conveyor, also called belt conveyor or belt conveyor, is an indispensable economic logistics conveying equipment for the composition of rhythmic flow line. According to its conveying capacity can be divided into heavy belt machine such as mining belt conveyor, light belt machine such as used in electronic plastics, food light industry, chemical and pharmaceutical industries.

The belt conveyor has strong conveying capacity, long conveying distance, simple structure and easy maintenance, and can easily implement programmed control and automatic operation. The continuous or intermittent movement of the conveyor belt is used to transport items below 100KG or powdery and granular items, and its operation is high-speed, stable, low noise, and can be transmitted up and down the slope.

Transmission principle characteristics

(1) The traction force of the belt conveyor is transmitted by the friction between the transmission drum and the tape, so the tape must be pulled tight with the tension device, so that the tape has a certain initial tension at the separation of the drum.

(2) The tape and the cargo run on the roller together. The tape is both a traction mechanism and a bearing mechanism, and there is no relative movement between the cargo and the tape, which eliminates the friction resistance between the tape and the cargo in operation. Because the roller is equipped with rolling bearings, there is rolling friction between the belt and the roller, so the running resistance is greatly reduced, which reduces the power consumption and increases the transportation distance. For a belt conveyor, the size of its tractive force transfer capacity is determined by the tension of the tape, the wrapping Angle of the tape on the drive drum and the friction coefficient between the tape and the drive drum. To ensure that the tape of the belt conveyor does not slip on the transmission drum and runs normally, corresponding measures should be taken according to different situations in production practice. Improving the transmission ability of traction force can be started from the following aspects:

(1) Increase the tension (initial tension). In the operation of the belt conveyor, the tape should be extended, resulting in a decrease in traction, so according to the situation, the tension device should be used to properly tighten the tape and increase the tension of the tape to improve traction.

(2) Increase the friction coefficient. The specific measures are: protect the wood lining or rubber and other liners covered on the transmission drum to increase the coefficient of friction, on the other hand to reduce the discharge of coal, to prevent the reduction of the coefficient of friction.

(3) Increase the wrapping Angle. Because of the poor working conditions and the large tractive force required, the belt conveyor in the underground uses double drum drive to increase the wrapping Angle.

Working principle

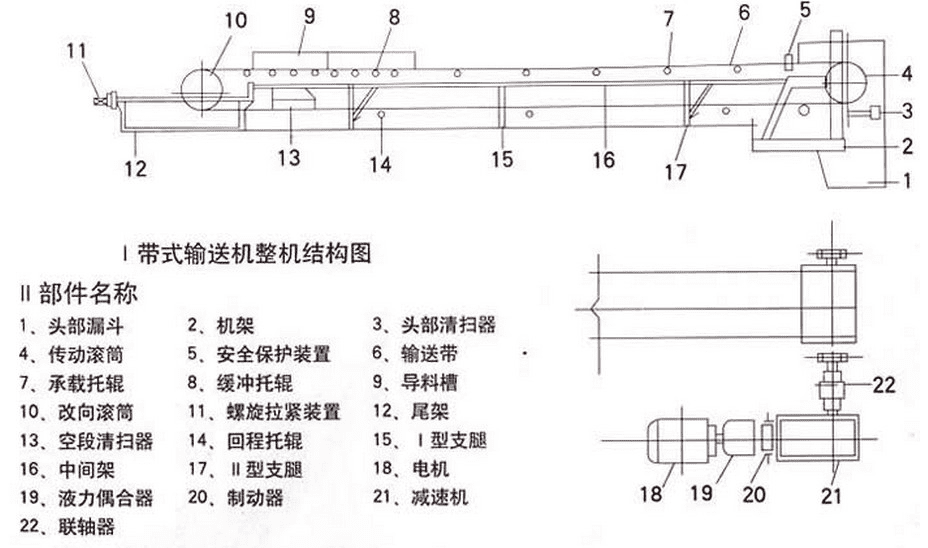

The belt conveyor is mainly composed of two end rollers and a closed conveyor belt tightly covered on them [1]. The drum that drives the conveyor belt to rotate is called the driving drum (transmission drum); Another drum that only changes the direction of the conveyor belt is called the reversing drum. The driving drum is driven by the motor through the reducer, and the conveyor belt is dragged by the friction between the driving drum and the conveyor belt. The driving roller is generally installed at the discharge end to increase traction and facilitate dragging. The material is fed by the feeding end, falls on the rotating conveyor belt, and is driven by the friction of the conveyor belt to the unloading end.

Scope of application

Can be used for horizontal transportation or inclined transportation, the use is very convenient, widely used in modern various industrial enterprises, such as: mine underground roadway, mine surface transportation system, open-pit mining and concentrator. According to the requirements of the conveying process, it can be a single conveying system, or a multiple conveying system or a horizontal or inclined conveying system with other conveying equipment to meet the needs of different layout lines.

Belt conveyor is widely used in metallurgy, coal, transportation, hydropower, chemical and other departments, because it has the advantages of large throughput, simple structure, convenient maintenance, low cost, strong versatility and so on.

Belt conveyors are also used in building materials, electricity, light industry, food, ports, ships and other sectors.

Copyright @ Huizhongxing All Rights Reserved 2024

Good

Admin on March 21, 2024The product is very good and has a beautiful appearance. We will cooperate more in the future.

Good

Admin on March 16, 2024The product quality is very good.

Good

Admin on March 09, 2024Fast construction period and excellent quality.

Good

Admin on March 09, 2024The after-sales service is excellent, and we can actively communicate and solve any problems!

Good

Admin on March 09, 2024I will repurchase in the future if needed!